This post contains affiliate links for which I receive compensation

Tension Problems with Monofilament Thread

How do I prevent bottom stitches from showing on top when using regular thread in the bobbin and monofiliment thread on top? I've tried changing the tension to lower numbers, but it doesn't seem to help.

Reply:

This is either a tension issue or a sewing machine needle issue.Quality monofilament thread for invisible machine applique should be soft, pliable and break easily. I'm assuming you're using a brand like YLI, SewArt, Superior, Sulky or Madeira. The size of this type of thread is .004--very, very fine.

Let's start with your sewing machine needle.

Try a Different Needle

Unlike our cotton quilting threads, monofilament is a fine, single extruded filament and not a twisted thread. As such, it doesn't fill up the hole made by the needle as it pierces the fabric.If the hole is big enough it is possible that the bobbin thread is coming up through it because it can.

If you are using an 80/12 needle, try the 75/11 or 70/10 and see if that helps. I usually use a 60/8 or 65/9 Microtex Sharp when I do my invisible applique. I have them on hand for machine quilting and I personally like the smaller hole.

Adjust the Tension

Since the bobbin thread is showing on the top, if it's a tension issue, then either the needle tension is too tight or the bobbin tension is too loose.Needle Tension

First check the thread path. Sometimes the monofilament thread gets twisted within the workings of your sewing machine...especially around the uptake arm.

Next, crank that tension number down even further. Even though I've mentioned that I reduce my tension by two numbers and then start testing, that is for my own particular Viking D1. It is quite possible you'll reduce your tension settings even further. Don't be afraid to reduce it all the way to '0' if that's what it takes for YOUR sewing machine to make a nice stitch.

Remember, that because this type of clear thread has it's own stretch, it creates tension as it passes through your sewing machine.

Bobbin Tension

First make sure that there is no lint caught in the tension mechanism of your bobbin case. Lint can 'hold open' the bobbin tension spring so that too little is applied to your bobbin thread. Remove the lint, the tension problem is solved.

If that's not it, then...

Yes, you can adjust the tension on your bobbin case.

I recommend this as a last resort because:

- The screw used to make the tension adjustment is so tiny

- You'll have to remember to return the screw to its original position once you've finished with the monofilament

- The screw can wear out

To tighten the bobbin tension, turn the screw to the right (remember 'righty-tighty') by about an 1/8 turn. Test. Adjust as necessary. If you have only one bobbin case, note the starting orientation of the screw so you can return it to its proper position.

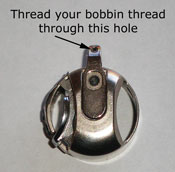

However, if you have the type of 'front loading' bobbin case, you have another alternative that you should try first.

I learned this trick while doing some Cactus Punch machine embroideries.

Threading through the hole adds a bit of extra tension on the bobbin thread so that it wouldn't show on the top of the finished embroidery. Neat trick!

Hopefully, one of these adjustments will make the difference in your stitch quality. Do let me know how it turns out!

Piecefully,

Julie Baird

Editor

Comments for Tension Problems with Monofilament Thread

|

||

|

||

|

Click here to add your own comments Click here to return to Machine Applique Questions...Answered!. |