This post contains affiliate links for which I receive compensation

Beginner Quilting Tips: Sewing Straight Stitches

by Michelle

(Midvale, UT)

I have just started quilting and very much loving it. It is my new hobby. Just not liking sewing up the squares since my sewing machine won't sew a straight seam. Also my quilt seems to not lay flat either even after pressing it and I even press the seams. What am I doing wrong?

Reply:

Your question seems to ask about both piecing and quilting, and I'll address each. But first let's talk about YOU and your SEWING MACHINE.As a new quilter, there are so many things to learn, that sometimes it seems as if you'll never get the hang of everything.

Make a date with your sewing machine...

One of the best things you can do for yourself is set aside some time to get really acquainted with your sewing machine...even if you've come from a sewing/garment construction background.Frequently we'll use two different threads when we quilt, one for the needle, one for the bobbin. Since sewing machines are designed to create a balanced stitch when the same thread is used in both, you need to be comfortable adjusting your tension. Visit Adjusting Sewing Machine Tension for help if you need it.

Check your sewing machine manual to see if and when you need to change the presser foot pressure. For my Viking sewing machine, I need to reduce the pressure setting when machine quilting with a walking foot. Acquaint yourself with the settings and location of the control.

Give your sewing machine a good cleaning. Consult your manual (again) to see if it needs to be lubricated. If so, be sure to use sewing machine oil.

Clean out the bobbin case regularly. Our cotton threads create lint build up which can effect how smooth the parts move against each other. A tiny bit of lint caught in the tension mechanism of your bobbin case can completely throw off your tension settings. So keep it clean!

Piecing and Stitch Quality

To create a nice straight stitch as you are piecing blocks, first take sewing test to check your seam allowance and tension settings.If the seam is puckered, one of your tensions is too tight. Do a quick check to make sure your needle thread hasn't caught on something in the thread path. If your spool is one that has a notch in the top to hold the thread tail, make sure the notched end is to the right on a horizontal spool pin. Then try reducing the needle tension just a tad and test.

If your machine isn't producing a nice straight stitch, there are two possible remedies:

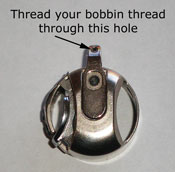

- If your machine has a front loading bobbin case...

...thread the bobbin thread through the hole in the arm.

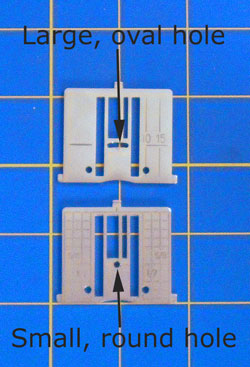

That way your bobbin thread feeds directly underneath your needle and not from the side. - Switch to a straight stitch throat plate.

Most sewing machines come with the zig zag throat plate, so you may have to purchase the additional throat plate. You'll know it is for straight stitching, because it has a small round hole instead of an oval.

There's one drawback to using this straight stitch throat plate...

...You MUST use the needle in the center position.

If you adjust your needle position to create the perfect 1/4 inch seam allowance, you'll be breaking needles, as the needle will hit the plate instead of the hole.

The benefit of using this plate is the hole is smaller. Your needle can't 'push' extra fabric through it and distort your stitches.

These two things will go a long way towards creating a nice straight stitch.

If you find that your stitch quality changes for the worse during piecing, change your sewing machine needle. Needles are easily damaged by sewing over pins. Once its point is nicked, the stitch quality goes down hill. Changing it is an an easy, cheap fix.

I hope this has been helpful to you. I'll answer the second part of your question in a separate post and put the link here when it's written. Thank you!

Piecefully,

Julie Baird

Editor

Comments for Beginner Quilting Tips: Sewing Straight Stitches

|

||

|

||